Precision Manufacturing for Electronics Applications

Thin-Wall, High-Gloss, Two-Shot and Metal-Hybrid Solutions from Design to Production

FORESHOT provides integrated manufacturing for electronic appearance and structural components, supporting thin-wall molding, high-gloss surfaces, two-shot overmolding, insert-molding and metal-hybrid structures. With expertise across PC, communications and consumer electronics, we help brands turn early design concepts into stable mass-production through precise mold development, optimized molding parameters, automated assembly and strict quality validation. Our one-stop process shortens time-to-market, reduces defects, ensures cosmetic consistency and enables reliable performance for high-volume or high-mix product lines.

FORESHOT's Core Manufacturing Capabilities

With cross-disciplinary engineering expertise and extensive mass-production experience, FORESHOT provides a reliable technical foundation for electronic appearance and structural components. Our capabilities integrate mold design, precision molding, metal stamping and automated assembly to support stable and repeatable production for computers, communications and consumer electronics devices.

Technical Capabilities and Advantages

Building on these core competencies, the following key technologies further enhance FORESHOT's ability to support complex electronic applications.

Micro Injection Molding

Ideal for thin-wall parts, miniature housings and small acoustic or functional components. Helps reduce burrs, warpage and dimensional variation for high-precision electronics.

RHCM / High-Gloss Injection

Enhances surface gloss, eliminates weld lines and achieves cosmetic uniformity for visible housings used in speakers, routers, handheld devices and portable electronics.

Two-Shot / Multi-Color Injection

Supports dual-color housings, soft-touch functional keys and integrated light-guide or indicator windows, improving user interface and aesthetic consistency.

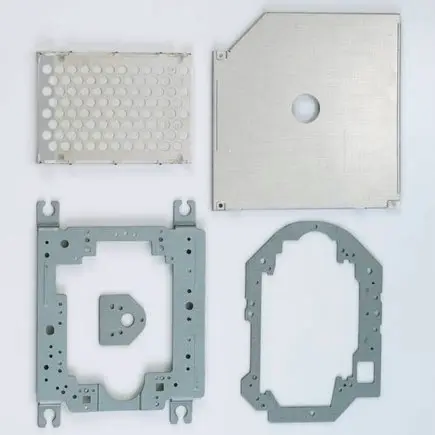

Metal Stamping & Hybrid Structures

Offers high-precision brackets, frames and EMI-shielding components. Provides surface treatment options including coating, anodizing and electroplating for mechanical strength and visual durability.

Automated and Semi-Automated Assembly

Integrates molding, stamping and assembly to reduce human error, stabilize output and support high-volume or high-mix production for electronics.

Case Studies

Technical Specifications

| Specification | Description |

|---|---|

| Molding Capability | Precision injection molding, two-shot molding, RHCM high-gloss molding, LSR/LSM silicone molding |

| Dimensional Tolerance | ±0.02 mm, depending on geometry and part size |

| Materials | ABS / PC / PC+ABS / PC+GF / PA+GF / PBT / LSR; metal stamping in SPCC, SUS, AL |

| Surface Treatment | Spray painting (PU/UV), electroplating, anodizing, laser marking, UV coating |

| Quality Assurance | 3D STEP review, DRW verification, DFM, FAI, IPQC, reliability testing, batch traceability |

Customer Benefits

- Shortened Time-to-Market:Using UG-based design and Moldex3D mold-flow analysis, we accelerate validation from DFM review to first-article samples within weeks.

- Improved Appearance Consistency:RHCM and optimized hot-runner design combined with strict process control significantly improve surface quality and yield for high-gloss applications.

- Reduced Overall Cost: Integrated molding, stamping and assembly streamline the supply chain, lowering tooling transfer, logistics coordination and multi-supplier management costs.

- Gallery

- Networking device housing made with precision molding.

- Headphone housings produced with high-gloss molding.

- Silicone wristband molded with LSR technology.

- FORESHOT technology applied in Silicon wristband.

- FORESHOT technology applied in POS hardware.

- FORESHOT technology applied in POS hardware.

- FORESHOT technology applied in 3D eye frame.

- FORESHOT technology applied in Bluetooth portable speaker.

- FORESHOT technology applied in Silicon & Rubber ear plugs.

- FORESHOT technology applied in Multimedia player.

- FORESHOT technology applied in Bluetooth earphones.

- FORESHOT technology applied in Bluetooth earphones.

- FORESHOT technology applied in Game Pad.

- FORESHOT technology applied in Boombox.

- FORESHOT technology applied in Game Controller.

- FORESHOT technology applied in Game Controller.

- FORESHOT technology applied in Bluetooth Speaker.

- FORESHOT technology applied in Wifi Router.

- FORESHOT technology applied in Headphones.

- FORESHOT technology applied in Headphones.

- Related Products

Precision Manufacturing for Electronics Applications | Custom Manufacturing Solutions for Electronics, Medical & Automotive Industries

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)