Milestone

FORESHOT-Milestone

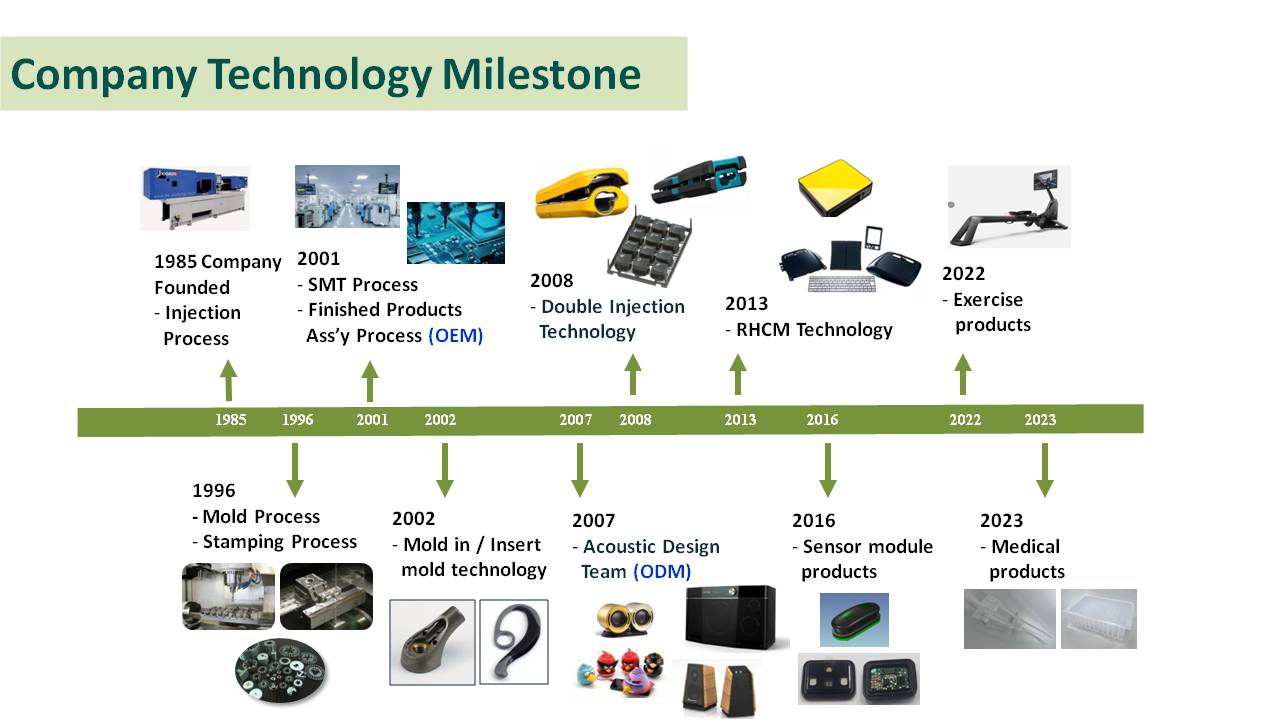

FORESHOT founded in 1985 has more than 40 years in plastic injection industry. In order to give customers more comprehensive service, FORESHOT integration of OEM / ODM and continue develop new technology. FORESHOT service Including molding design、Plastic injection molding、Metal Stamping、Assembly service to final product It's let customer satisfied.

FORESHOT provides plastic injection molding services: LSR/LSM、Double-shot Injection Molding、Insert Injection Molding、Micro Injection Molding、Thin-wall Injection Molding、RHCM、Precision Injection Molding、Metal Stamping、SMT、Assembly service. FORESHOT technology service are applied in Computers / Communications / Consumer electronics、SMT & Electronic component part、Medical Appliances and Accessories、Optical Components and Vehicle Accessories.

In fact, FORESHOT has been devoted in Technology innovation for the best productivity. Therefore, RD team of FORESHOT is been studying innovation in the Acoustic design、Optoelectronic design、Electronic engineering, Mechanical engineering、Industrial design and Product planning.

The most important thing is that FORESHOT can provide technology support of product development and solutions for precise cost control, and the maximum production capacity. The R & D team of FORESHOT has been awarded numerous patents owing to its strong professional background. What's more, all FORESHOT products are environmentally friendly and designed for easy recycling, which minimizes their impact to the environment.

Media Gallerys

- FORESHOT Received an Excellent Vendor Award from Leica.

- FORESHOT Received an Excellent Vendor Award from AVAYA.

Milestone

| Time | Achievement |

|---|---|

| 2025 | Received a Golden Award from SWISSCOM. Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET. |

| 2024 | Greenhouse Gas Verification Opinion. |

| 2019 | Received a Best Component Supplier from AVAYA. Received a Supplier Day from AVAYA. Foreshot Dayuan Factory(Taiwan) Restart System & Accessory Assembly Lines. |

| 2018 | Received an Excellent Vendor Award from Leica. Received an Excellent Vendor Award(Client Centric) from Sagemcom. Received an Excellent Vendor Award from AVAYA. Import Mold Monitoring System. |

| 2017 | Received an Excellent Vendor Award(Team Power) from Sagemcom. Import JSW High Speed Injection Molding Machine. Import Sodick-V-LINE Electric Hybrid Injection Molding Machine. Expanded product line: LSM Wristband. |

| 2016 | Expanded product line: Vehicle Accessories, Headphone with Sensor. |

| 2014 | Import the 800T Microcomputer Energy-Saving Servo Pump Injection Molding Machine. |

| 2013 | Expanded product line: Wireless Game Pad, Wireless Game Controller, Wireless Mono Boombox, the built-in Bluetooth 2.1 speaker, NFC Wireless Portable speaker. Expanded for more productivity in Kun Shan, FORESHOT Group - ForeTech. |

| 2012 | Expanded product line: Electronic Vehicle accessories, Mini Projector, Stylish Speaker, 2.4G Wireless Home Theater. Activated High Gloss / Weld Line free Injection Molding with RHCM process. Developed multi-cavity mold for LCD-TV, completed 1 frame and 4 brackets in on-time. |

| 2011 | Expanded product line: Docking speaker with Bluetooth, Wireless Home Theater with Bluetooth. |

| 2010 | Won prestigious Red Dot Award: Product Design - FORESHOT UP-001 portable speaker. |

| 2009 | Expanded product line: Networking device、Card reader. Won GOLDEN PIN DESIGN AWARD-FORESHOT UP-001 portable speaker. |

| 2008 | Received an Excellent Vendor Award from Wistron. Expanded product line: LCD TV frame. |

| 2007 | Set up FORESHOT Square LED in Beijing Capital International Airport. Expanded product line: Headphones. |

| 2006 | Expanded product line: TV / Notebook frame |

| 2004 | Passed the ISO 14001 Authentication. Expanded product line: Electronic product series with Bluetooth, Speaker. |

| 2002 | Passed the ISO 9001:2000 Authentication. |

| 2001 | Selected as the Outstanding OEM / ODM Partner by Plantronics. |

| 2000 | Selected as the Outstanding OEM / ODM Partner by ACER. |

| 1997 | Expanded Dayuan Plant and established a Stamping Plant. |

| 1996 | Received a 20-Years Partnership Award from ACER, and became ACER's Certified Supplier. |

| 1995 | Established Dayuan Plant, Expanded the CD ROM Production Line and Established Mold Plant. |

| 1994 | Passed the ISO 9002 Authentication. |

| 1993 | Received an Excellent Vendor Award from ACER. |

| 1988 | Selected as the Best OEM / ODM by ACER. |

| 1987 | Expanded product line: Production and Assembling of Notebook Computer Parts. |

| 1986 | UL Certified in Forming / Spray Painting / Assembly. |

| 1985 | The Company was established with a capital of 2 Million NT Dollars, Xinzhuang plant started to produce keyboard and became a professional Computer Keyboard manufacturer. |

- Received an Gold Award (Sustainable Development Programme) from Swisscom.

- Received an Excellent Vendor Award(Best Quality Support Award) from Foxconn Industrial Internet.

- Greenhouse Gas Verification Opinion.

- Received an Excellent Vendor Award(Best Component Supplier) from AVAYA.

- Received an Excellent Vendor Award(Best Component Supplier) from AVAYA.

- Received an Excellent Vendor Award(Team Power) from Sagemcom.

- Received an Excellent Vendor Award(Team Power) from Sagemcom.

- Received an Excellent Vendor Award(Client Centric) from Sagemcom.

- Mold monitoring system can effectively monitor the abnormal situation of the mold.

- Import advanced JSW High Speed Injection Molding Machine, provides precise and stable injection quality.

- Import advanced Sodick-V-LINE Electric Hybrid Injection Molding Machine, provides precise and stable injection quality.

Milestone | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)