Metal Stamping

Sheet Metal,Metal Parts, Mechanical Parts, Electronic Components, Vehicle Accessories.

Metal stamping is an important manufacturing process its can according that what need shape and features to stamping. Its advantage are high production rate, consistent and low cost. Its technology are apply in much industry such as automotive, heavy industry, Electrical and Electronics industry, electronic components, hardware fittings and Vehicle Accessories.

FORESHOT could do: Design and development of continuous stamping、Stamping tool components、Design and manufacturing of continuous stamping tool、 various stamping metal parts、Sheet Metal、Sheet Metal Fabrication and Mechanical Parts.

With Metal Stamping unit established for years, FORESHOT is continually upholding the attitudes of "client satisfaction" and "make our clients more competitive" to make efforts in development and product improvement. Therefore, to present our products are with the best quality and excellent service to our clients. The Metal Stamping Unit of FORESHOT was certified with ISO 9002 in 2000.

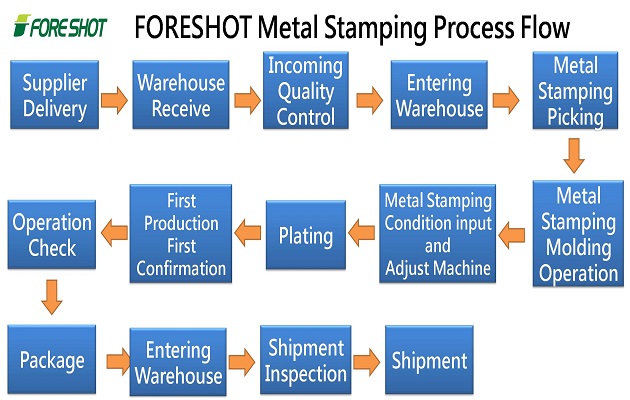

FORESHOT Metal Stamping Process Flow

In metal-stamping process, it is important to stamp the precise product based on customer requirement.The stability of the metal forming process is normally dependant on the material and process parameters.

A slight change in a process parameter, like material properties or lubrication condition, can produce a defect that can damage the tool.

The quality practitioners and production operators must aware any unnatural variation (UV) during in-progress process to avoid defective products. FORESHOT metal stamping process flow,as shown in the following picture.

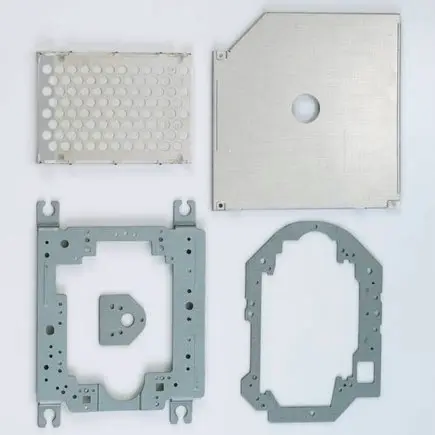

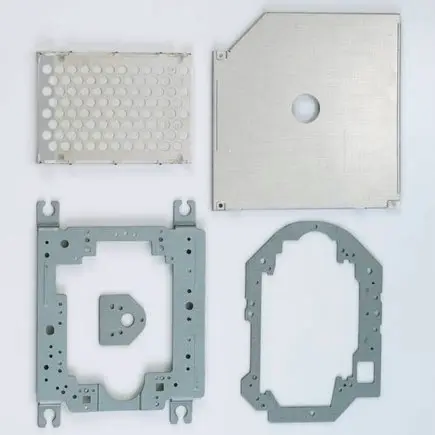

Case Studies

Features

- A lightweight, highly rigidity product is available.

- Good productivity and suitable for mass production.

- A product of uniform quality can be obtained.

- High material utilization, good tailorability and recyclability.

Foreshot Capability of design and manufacturing

- Design of stamping tool components.

- Design and manufacturing of continuous stamping tool.

- Stamping OEM.

- Design and development of continuous stamping.

- Various stamping metal parts.

- Other metal stamping manufacture and design.

- Gallery

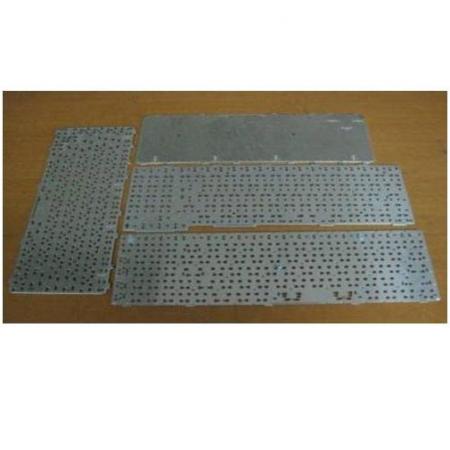

- Metal stamping apply in Computer Case

- Metal stamping apply in Server Case

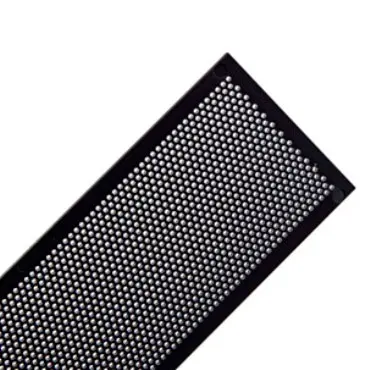

- Metal stamping apply in Electronic Components

- Metal stamping apply in Electronic Components

- Metal stamping apply in Hardware Products

- Metal stamping apply in Electronic Components

- Metal stamping apply in Vehicle Accessories

- Metal Stamping Machine

- Related Serivce

Metal Stamping | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from Metal Stamping, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)