Vehicle Accessories

Apply in Plastic Injection Molding / Metal Stamping / SMT / Assembly Service

FORESHOT founded in 1985 has more than 30 years in plastic injection industry. In order to give customers more comprehensive service, FORESHOT integration of OEM/ODM and continue develop new technology. FORESHOT Service Including Molding Design, Plastic Injection Molding, Metal Stamping, Assembly Service to Final Product It's let customer satisfied.

In addition, R&D team is working on technology application and innovation for product integration and better productivity. What's more, FORESHOT insists to follow standards of international quality certification.

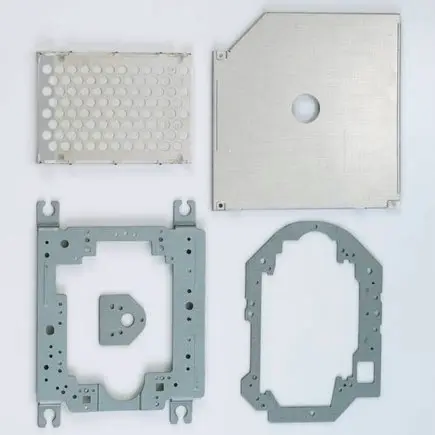

The technology services are Plastic Injection Molding、Metal Stamping、SMT and Assembly Service, which are applied in Vehicle Accessories: Motorcycle Shell、Mudguard、Car Connector and Battery Set.

- Gallery

- FORESHOT technology applied in Motorcycle storage box.

- FORESHOT technology applied in Battery set.

- FORESHOT technology applied in Vehicle Accessories.

- FORESHOT technology applied in Vehicle Accessories.

- FORESHOT technology applied in Motorcycle Parts.

- FORESHOT technology applied in Motorcycle Fender.

- Related Products

Vehicle Accessories | Custom Manufacturing Solutions for Electronics, Medical & Automotive Industries

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)