Insert Injection Molding

Insert Molding, Mold In Injection Molding,OverMolding

Insert Injection Molding could be called Insert Molding or Over Molding, which a sole part is formed using two or more different materials in combination. In Insert injection Molding can either be incorporated at the time of the molding process or can be inserted as post molding operation.

Especially, if properly selected two kinds of material, it will obtain a strong bonding of the molded part. Therefore, the used of primers or adhesive was no longer required to achieve an optimum bond between two materials.

This process of insert injection molding results in a strong bonded and integrated assembly with plastic encapsulated inserts.Insert molding made from the following material :Ceramic、Plastic、Metal and The substance that can withstand the high temperature of injection molding process.

What industries commonly use insert molded parts?

Insert molding is commonly used in a broad range of industries, including medical, automotive, consumer products and electronic components. Common applications include electronic housings, knobs and dials and hand-held devices.

Foreshot according product requirements and design, through Insert Molding combines metal and plastics, or multiple combinations of materials and components into a single unit, this feature let customer enhanced design flexibility, such as Electronic Components、Precision Components、Vehicle Accessories and Medical Appliances and Accessories etc.

FORESHOT Insert Injection Molding process flow,as shown in the following picture:

.jpg)

Case Studies

Advantages

- Reduces assembly.

- Labor costs.

- Reduces the size and weight of the part.

- Improves component reliability.

- Delivers improved part strength.

- Structure with enhanced design flexibility.

Differences in the process between Insert Injection Molding and Conventional Injection Molding.

| Conventional Injection Molding | Insert Injection Molding | |

|---|---|---|

| Materials | Metal and plastic boxes | |

| Tolerance | Not strict | Stringent |

| Design Difficulty | Need to consider the components and assembly gap | The number of combined features needs to be considered |

| Design time | Longer | Short |

| Mold Making | Low precision (low cost) | High precision (high cost) |

| Assembly steps | Subsequent manual assembly | No post processing required |

| Assembly issues | Having foreign components and scratches problems | No foreign components and scratches problems |

Applications

- Insert Injection Molding is frequently applied in accessories of Computers / Communications / Consumer electronics、Electronic Components、Precision Components、Vehicle Accessories and Medical Appliances and Accessories.

- Gallery

- Insert Injection Molding Applied in Medical Appliances and Accessories.

- Insert Injection Molding Applied in Computers / Communications / Consumer Components.

- Insert Injection Molding Applied in Vehicle Accessories Components.

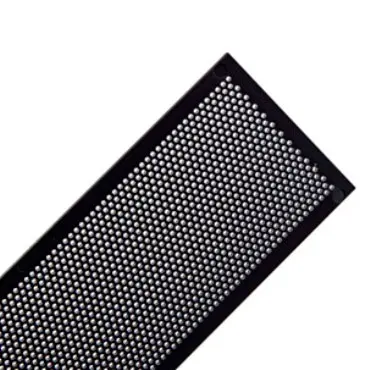

- Insert Injection Molding Applied in Precision Components.

- Insert Injection Molding Applied in Precision Components.

- Insert Injection Molding Machine.

- Related Serivce

Insert Injection Molding | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from Insert Injection Molding, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)