LSR/LSM Injection Molding

Liquid Silicone Rubber(LSR), Liquid Silicone Injection Molding(LSM)

LSR/LSM Injection Molding

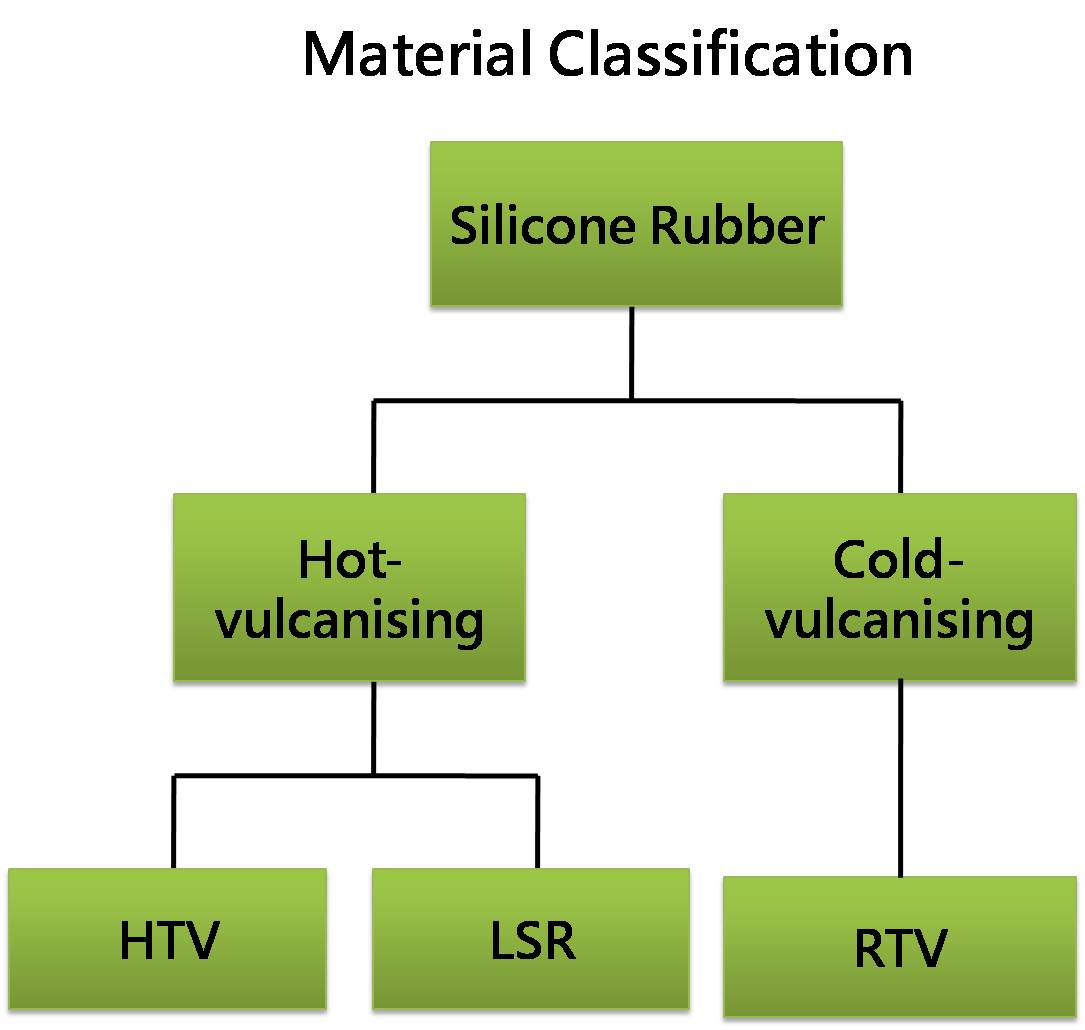

Organosilicone known as Silicone, it is a type of molecular chain and a non-breakable Polysiloxane that it's a silicon atom combined with oxygen atom.

Silicone has various kinds of material、unique functions and wide range of uses. It's an indispensable chemical materials that also call 「technology development catalyst」. As shown below is material classification.

FORESHOT has LSR/LSM Liquid Silicone Injection Molding technology and offers variety types of mold to satisfy different demands, such as V-Cut without flash molding type and precision Cold Runner type.

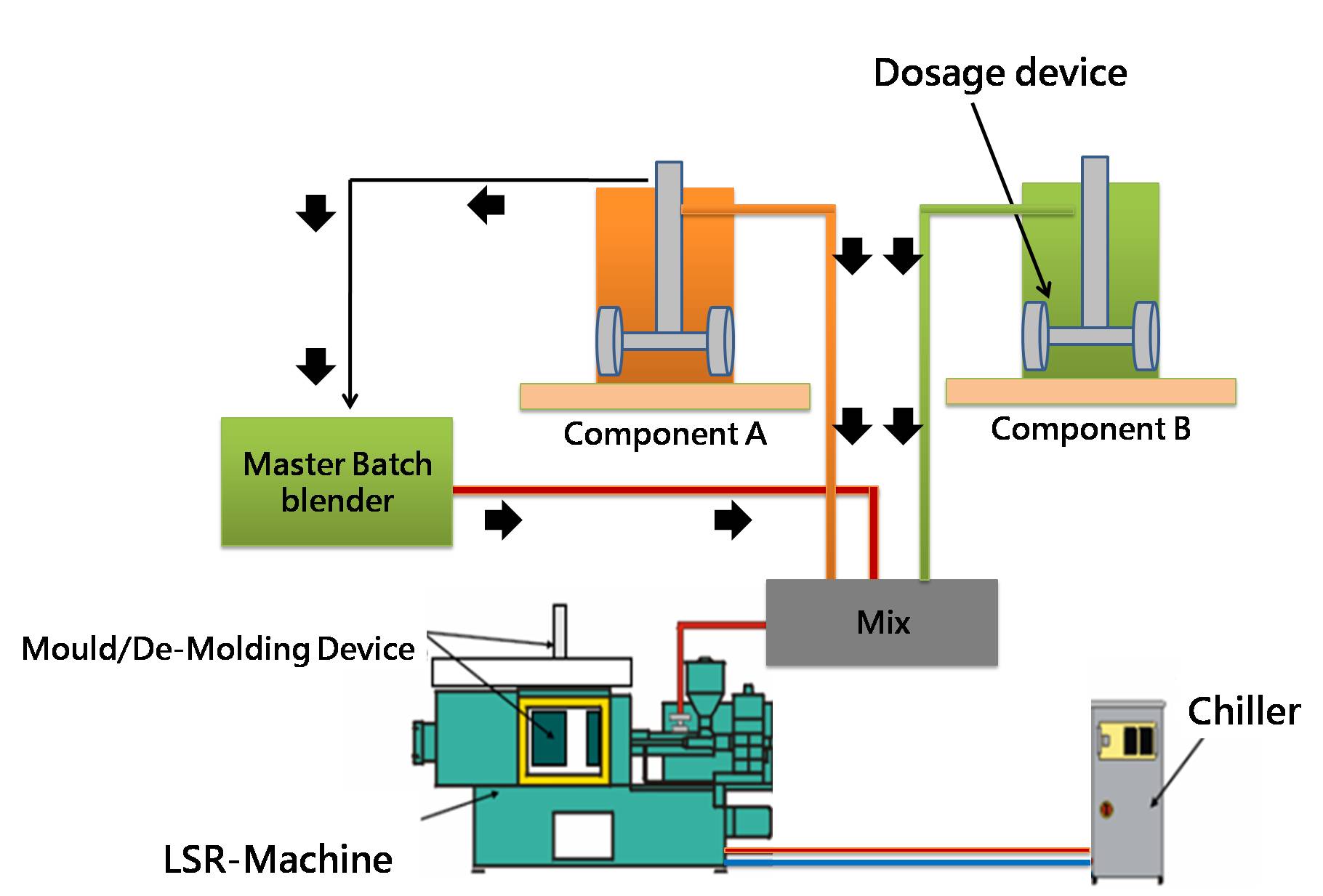

The method of Liquid Silicone injection molding is injection molding after mixing A, B liquids,as shown below.

.jpg)

LSR is injection molding with the liquid silicone,although it's a high temperature hardening silicone but it has a lower viscosity than HTV and other elastomers.

LSR form is liquid, so it can be supplied to the injection molding machine continuously, thereby making product automatically formed.

Therefore, it not only improve production efficiency, but also has excellent physical properties, as shown below.

1.jpg)

Case Studies

Features

- High Temp Resistance: Outstanding material property in the condition of high temperature (over 200°C) for long time.

- Low Temp Resistance: Outstanding flexibility in the condition of low temperature (-70°C).

- Low Compression Set: Possible to be used for application such as sealing and gasket due to outstanding compressed permanent strain.

- Chemical Resistance: Outstanding oil resistance, solvent resistance and chemical resistance, aniline, alcohol or alkali cannot be invaded.

- Electric Property: Having hydrophobic for water and excellent electric insulation.

Applications

- LSR/LSM Injection Molding could be applied in Computers / Communications / Consumer Electronics: Ear Plugs, Smart Watch Band, Wristband, Medical Products.

- Gallery

- Related Serivce

LSR/LSM Injection Molding | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from LSR/LSM Injection Molding, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)