Drone Plastic Components & Assembly Solutions

Precision injection molding for lightweight, high-strength drone structural components

Unmanned aerial vehicles (UAVs) place high demands on plastic components in terms of lightweight design, structural strength, and dimensional stability. Drone housings, frames, and internal structural parts must withstand vibration, impact, and environmental exposure while maintaining consistent performance during flight. At the same time, manufacturers face challenges in balancing weight reduction, material durability, and stable mass production.

FORESHOT supports drone manufacturers by providing precision injection molding and assembly solutions tailored to these application requirements. By combining thin-wall molding techniques, reinforced engineering plastics, and tight tolerance control, we help customers develop reliable plastic components suitable for consumer, commercial, industrial, and professional-grade drone platforms.

Media Gallerys

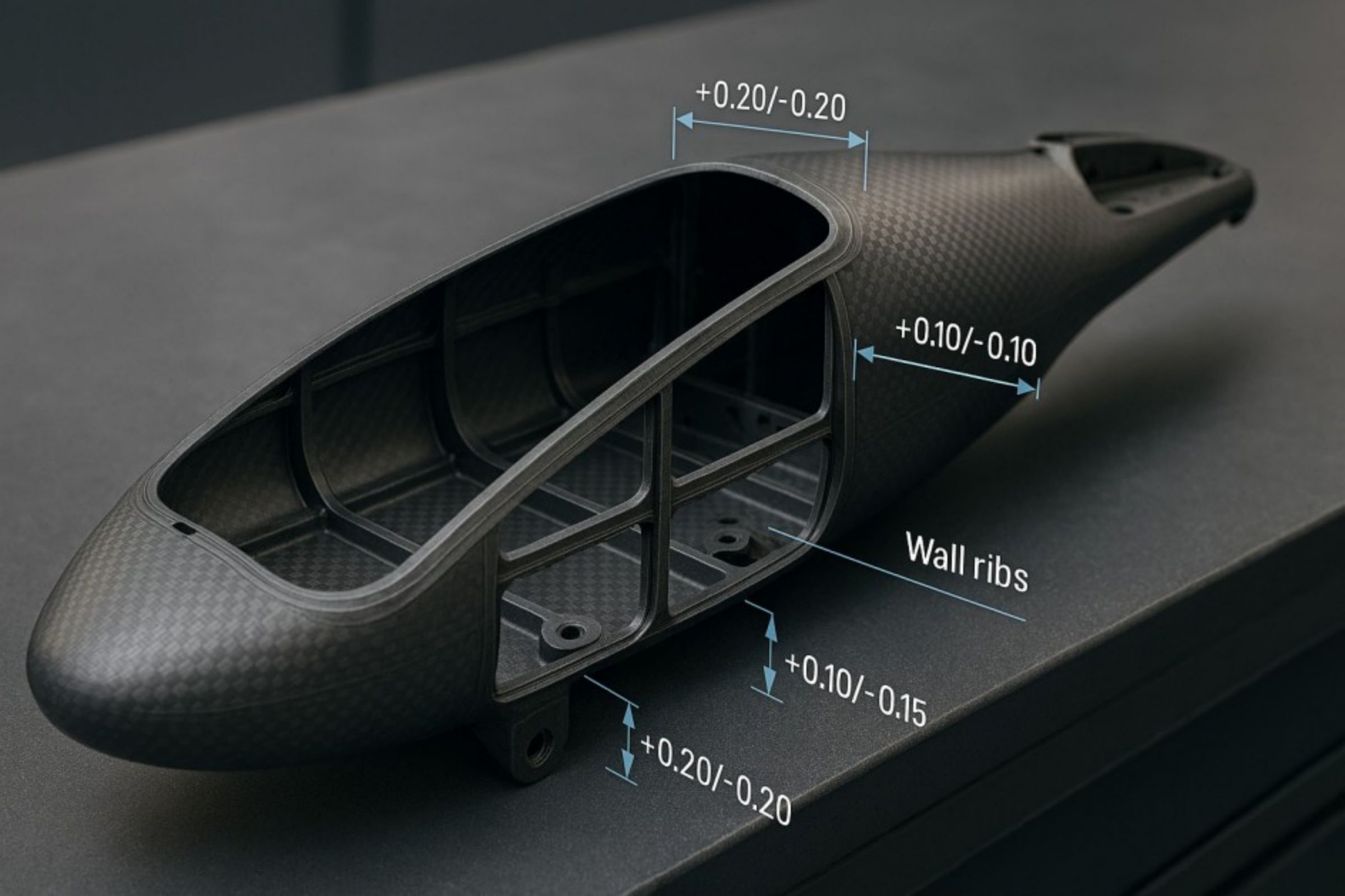

- Carbon Fiber Reinforced Housing,Thin-wall structure, fiber-reinforced, RHCM high-gloss surface treatment.

- FORESHOT Technology Applied in Drone Components

- FORESHOT Technology Applied in Drone Components

- FORESHOT Technology Applied in Drone Components

Application-Driven Manufacturing Capabilities

Drone plastic components must meet strict requirements for weight reduction, structural strength, and assembly reliability. To support these application needs, FORESHOT combines precision molding, advanced materials, and integrated assembly services. This manufacturing approach helps drone developers reduce design risk, maintain consistent quality, and streamline the transition from component production to system-level integration.

Thin-Wall & Precision Injection

0.6–1.2 mm thin-wall molding with ±0.03 mm tolerance control to support lightweight drone structures while maintaining dimensional stability.

Composite Material Molding

Integration of PA+GF and carbon fiber–reinforced composites with surface finishing to enhance strength, stiffness, and durability for drone components.

One-Stop Assembly

Injection molding combined with PCBA, functional testing, and packaging to simplify coordination and improve manufacturing efficiency for drone projects.

Manufacturing Specifications for Drone Plastic Components

- Wall Thickness: 0.6–1.2 mm

- Precision: ±0.03 mm

- Materials: PA6+GF30 / PC+GF / CF reinforced blends

- Testing: Vibration (MIL-STD), thermal cycling, UV resistance

Case Studies

Drone Applications Supported

FORESHOT’s plastic components are designed to support a wide range of drone application scenarios with different performance and environmental requirements.

- Consumer-grade aerial photography

- Commercial mapping

- Agricultural spraying

- Industrial inspection

- Defense and professional applications

Case Studies

Drone Plastic Components & Assembly Solutions | Custom Manufacturing Solutions for Electronics, Medical & Automotive Industries

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)