Micro Injection Molding

Micro Injection, Micro Component Injection Molding,High Speed Injection Molding

Micro Injection Molding is combined the special design of barrel and injection equipment to precisely control injection volume for steady capability of plastic material. In addition, high efficiency and low cost are advantages of micro injection molding.

Micro Injection Molding can be divided into Micro Injection and Micro component Injection Molding. Owing to new technological advances, Biotechnology, Medicine, Electro-optical industry, Computer / Communication / Consumer Electronics are toward small and precision to design, so that can't traditional injection molding do its.

Micro Injection Molding need three part to work: High polymer material, Micro Molding, Micro Injection Molding Machine, Foreshot have advances technology and equipment to satisfy with customer and finish high quality product.

FORESHOT has advances Sodick V-Line system to satisfy customer requirements.

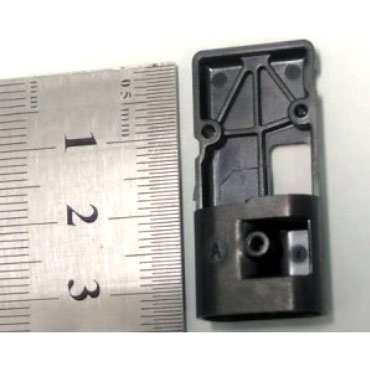

Micro Injection Molding is able to do Precision Components, Electronic Components, Micro mechanism such as camera, CD-ROM, Gears of printer, Headphones accessories, LED light bulbs, Lens holder and etc.

Advantages

- High Injection Speed.

- High Stability and Precision.

- Manufacture Micro Component and Micro Electronic Products.

- Reacting Quickly.

Differences in the process between Micro Injection Molding Machine and Conventional Injection Molding Machine

| Micro Injection Molding Machine | Traditional Injection Molding Machine | |

|---|---|---|

| Injection Speed | 800mm/s | Under 200mm/s |

| Reaction Speed | Fast | General |

| Control Accuracy | Precise | Unstable |

| Injection Volume | Precise | Unstable |

- Gallery

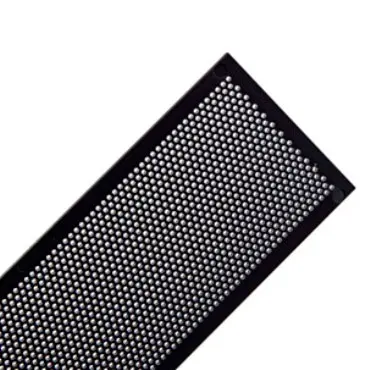

- Micro Injection Molding applied in Micro component.

- Micro Injection Molding applied in Micro component.

- Micro Injection Molding applied in Micro component.

- Micro Injection Molding applied in Micro component.

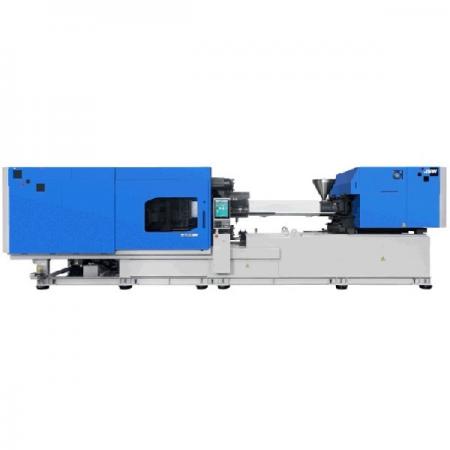

- FORESHOT has advances JSW high-speed injection machine.

- FORESHOT has advances Sodick V-Line system.

- Related Serivce

Micro Injection Molding | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from Micro Injection Molding, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)