SMT

Surface Mount Technology,SMT Assembly,SMT Process

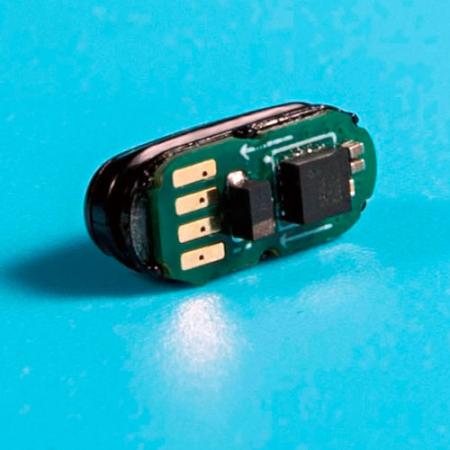

Surface-Mount Technology (SMT) is a term for a relatively modern style of printed circuit board design. The vast majority of commercial electronics are all about complex circuitry fitting in small spaces. In SMT, instead of putting wire leads into holes drilled in the circuit board, components and elements are mounted directly onto the surface of the board. Due to its efficiency and effectiveness, SMT has widely replaced through-hole technology methods for constructing PCBs.

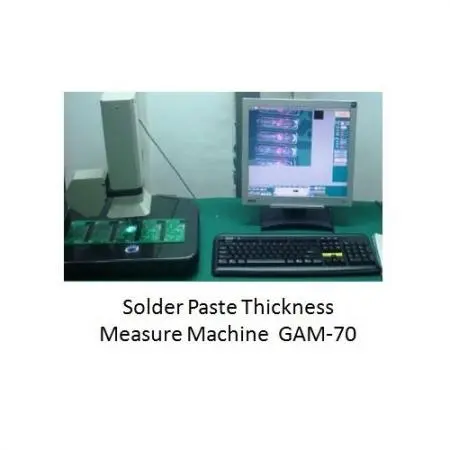

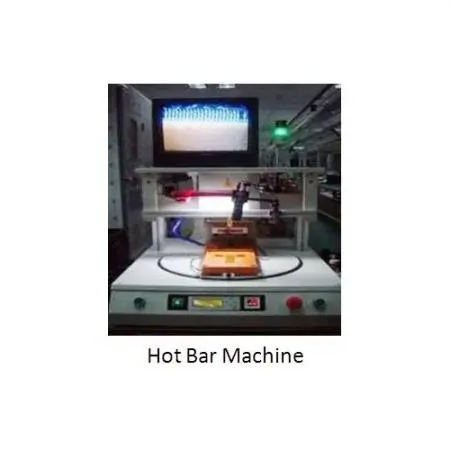

FORESHOT provides One-Stop shopping service from material procurement to assembly service. FORESHOT also offers the services of grouping and machining of product processing such as SMT / DIP PCB grouping, spray painting and printing, product assembly, packaging, SMT Assembly,SMT Process, EMS(Electronic Manufacturing Services) and Electronic Components etc. In addition, we have test service for PCBA (Printed Circuit Board Assembly) and final goods test.

When Should Surface Mounted Technology be Used?

- Your products must be very small / compact.

- Your products must be able to accommodate large volumes of memory.

- Your final product needs to be sleek and light despite component density.

- Your product will need to be able to function at high speed / frequencies.

- You need to produce large quantities with automated technology.

- Your product must be able to accommodate a great deal of large, high lead-count complex ICs.

Case Studies

Advantages

- SMT parts and components that actually cost less than their through-hole counterparts.

- The primary advantage to SMT, is size.

- Mass production.

- Higher component density.

- Less holes need to be drilled on circuit boards.

- Either side of a circuit board can have components placed on it.

Foreshot Production Lines

| Foreshot (Taiwan) | ZhongShan | DongGuan (Qingxi) | KunShan | Total | |

|---|---|---|---|---|---|

| Assembly Line | - | 18 | 11 | 8 | 37 |

| Injection Machine | 3 (180 ~ 350T) | 96 (45 ~ 600T) | 112 (50 ~ 2200T) | 92 (35 ~ 650T) | 298 (35 ~ 2, 200T) |

| Stamping Machine | - | - | 62 (1.5 - 400T) | - | 62 (1.5 - 400T) |

| Plastic Welding | - | 6 | 4 | 6 | 16 |

| Printing | - | 21 | 16 | 22 | 59 |

| SMT | - | 4 | - | - | 4 |

| DIP | - | 2 | - | - | 2 |

| System Assembly | 4 | 4 | - | - | 8 |

- Gallery

- Related Serivce

SMT | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from SMT, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)