RHCM

Rapid Heat Cycle Molding,High gloss injection mold

Traditional plastic injection molding does often uneven surface gloss of products and floating or exposed fibers on the surface of the fiberglass reinforced plastic chassis、poor transferability、inject pressure excessive and inject pressure uneven that they make stress marks around the mold gate of the product.

Therefore, it is necessary printing and painting process to cover these surface defects. For high gloss products, insufficient brightness and uneven brightness cannot be covered by painting.

Therefore, FORESHOT develops and apply RHCM technology, not only solve the above problems but also solve traditional plastic injection molding in ultra-thin parts, thick parts and reduces the cycle time.

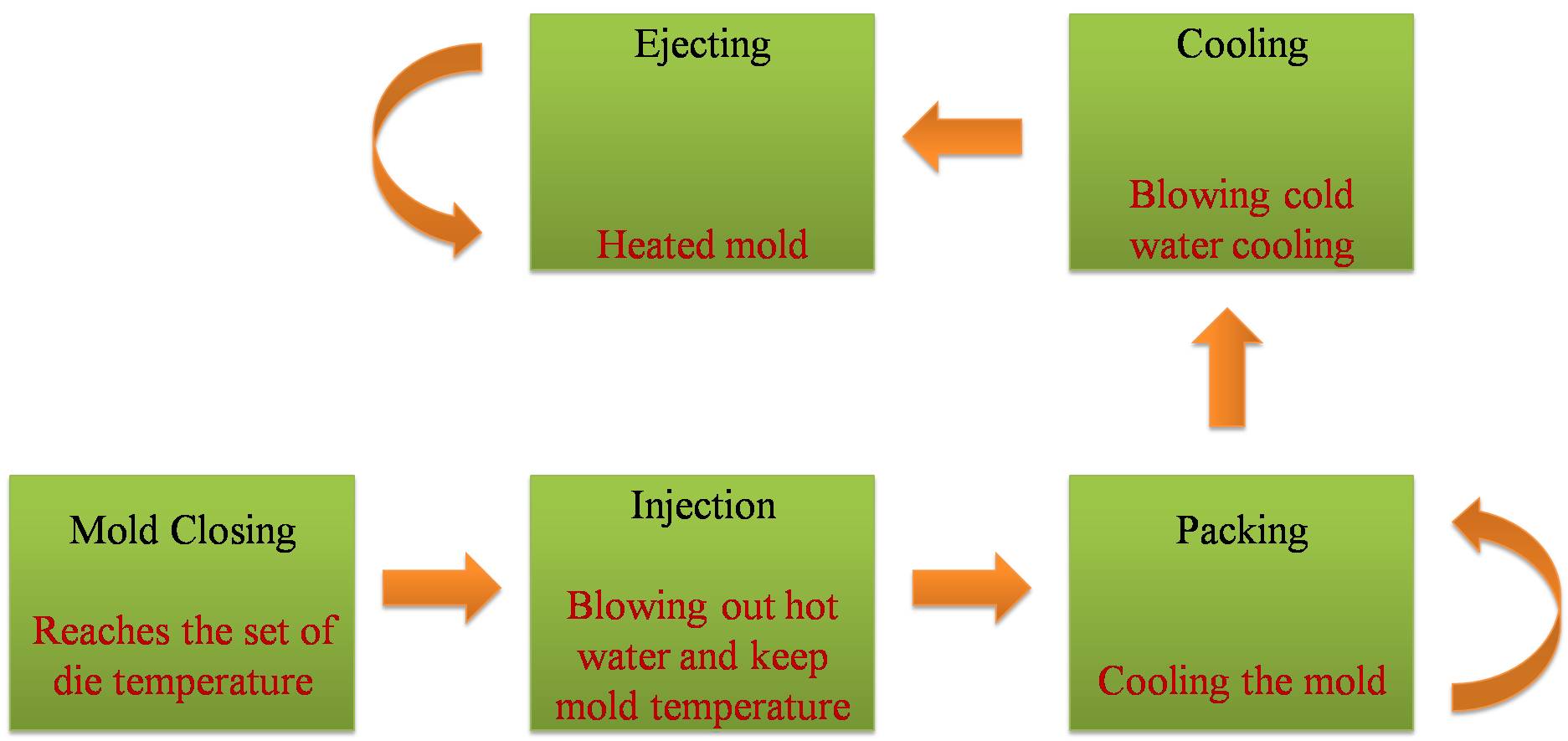

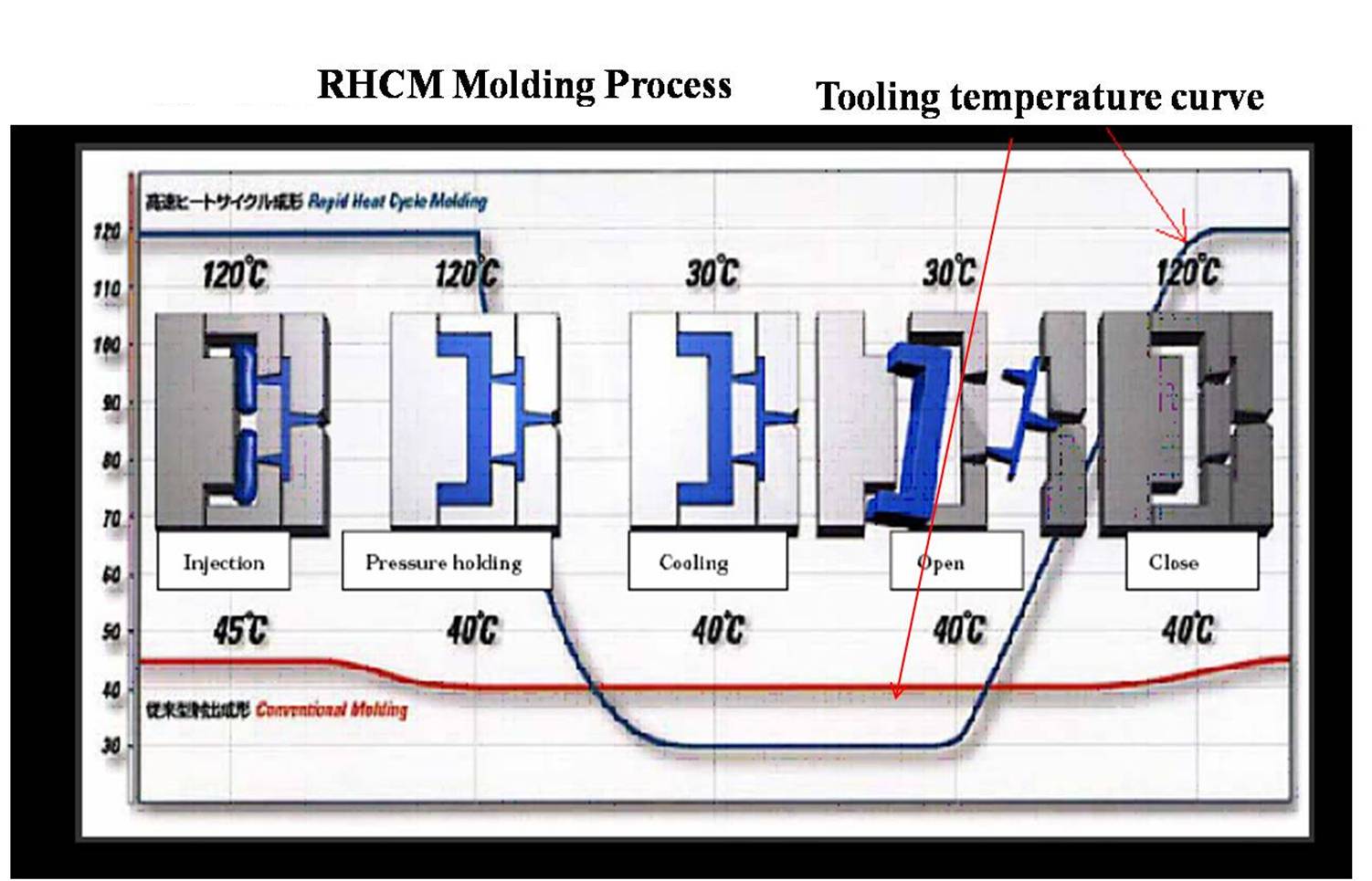

RHCM (Rapid Heat Cycle Molding) is rapidly changing the temperature of mold in injection process.This process is not only vanish the welding lines of the surface, but also improve the rate of product gloss and higher mold transferability.

High Gloss / Welding Line free Injection Molding with RHCM process is high-level technology, however, FORESHOT has been operated well in High Gloss / Welding Line free Injection Molding with RHCM process and invests many 250T ~ 1000T RHCM machines that they can do mass production and let customers satisfied.

FORESHOT adopts ARES high-gloss machine to provide advanced and stable RHCM technology and using of high-pressure water to instead steam in the water channel of the mold.

When the molds are matched in the injection machine then inject high temperature water and raise the mold temperature to the set value, and start injecting plastic into the cavity.

After the injection finished, injecting cold water let the mold temperature drops quickly to the set value. Open mold and blow air into the mold to blow away the cold water, finally complete the plastic injection molding process, as shown below.

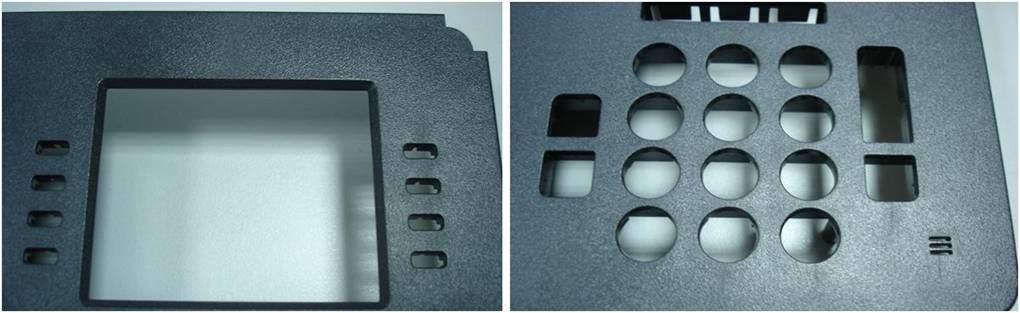

Many welding lines and uneven gloss when RHCM is not used

No welding lines and even gloss after using RHCM

Advantages

- High-gloss parts without welding lines.

- No floating or exposed fibers on the surface of the fiberglass reinforced plastic chassis.

- Avoid the stress mark around the mold gate.

- Thinner and lighter reinforced plastic parts can be made.

- Improve the rate of product gloss.

- Higher mold transferability.

Applications

- RHCM technology applied in plastic parts such as Network Communication equipments、Computers / Communications / Consumer Electronics、appearance parts of NB and LCD TV.

- Gallery

- RHCM applied in Network Communication equipments

- RHCM applied in Computers / Communications / Consumer electronics.

- RHCM applied in Computers / Communications / Consumer electronics.

- RHCM applied in Network Communication equipments.

- FORESHOT has advances RHCM machine.

- RHCM automation system。

- RHCM automation system。

- Related Serivce

RHCM | Certified Plastic Injection & Metal Part Manufacturer with Global Facilities

FORESHOT is a globally trusted OEM/ODM manufacturer with over 40 years of expertise in plastic injection molding, metal stamping, SMT, and system assembly. We offer vertically integrated solutions from RHCM, mold design to full product manufacturing, enabling streamlined workflows, reduced lead times, and enhanced product quality. Our advanced manufacturing facilities in Taiwan, China (KunShan, ZhongShan), and Vietnam (Bac Ninh) support diverse applications in electronics, medical devices, automotive components, optical systems, and communication equipment.

We specialize in advanced molding technologies such as LSR/LSM, double-shot, insert, thin-wall, and micro injection molding, along with RHCM for high-gloss, weld-line-free results. Supported by international certifications like ISO 9001, ISO 13485, and IATF 16949, our expert R&D teams help reduce defect rates, enhance production efficiency, and control costs. Whether you need high-precision components or full-scale production, FORESHOT is your trusted partner in OEM/ODM manufacturing.

Since 1985, FORESHOT has been delivering high-quality plastic injection molding and electronics manufacturing services. Backed by advanced technology and over 33 years of industry experience, FORESHOT is committed to meeting every customer's unique production requirements with precision and reliability.

FORESHOT's Advantages

0

Years of Progress

0

Global Bases

0

Current Client Number

0

Total Plant Area (ft²)